Technical Support

+3023990 20321Epoxy Coating - SERITAL

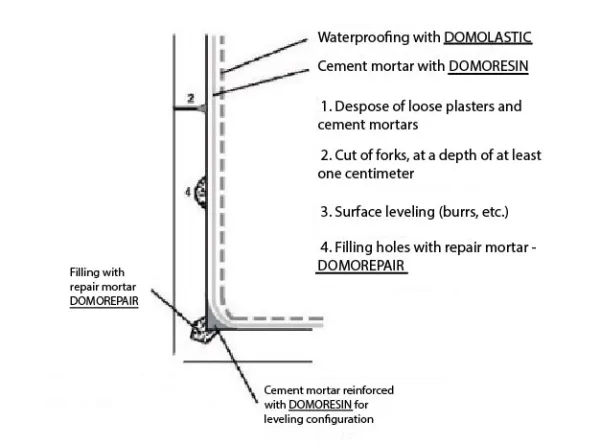

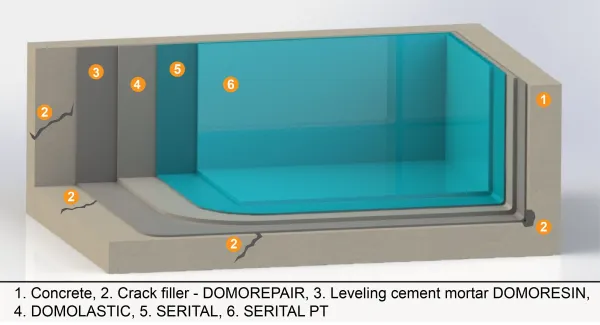

1. SUBSTRATE PREPARATION

– Clean the substrate (applying surface) of any loose objects, as well as peeled off paints and oils.

– Loose chippings from nests that may exist in parts of concrete.

– Hairpins and fids are cut at a depth of 3cm (at least).

– Wet the above parts and cover them with the repair mortar Domorepair.

– It is proposed to build a joint at the contact points of the vertical surfaces and the bottom of the pool with cement reinforced with the high quality building resin Domoresin SP.

– Afterwards, the pool is waterproofed with the flexible, two-component slurry, Domolastic W. Mixing ratio – Α (Liquid) : Β (powder) – 1 : 2.6 w/w. Add slowly component B (powder) into the component A (Liquid). Stir constantly and uninterruptedly with a low speed agitator until the mixture is fully homogeneous. The application is done with brush in 2 – 3 crossed layers.

NOTES:

1. In case of rough substrate, it is necessary to smooth the surfaces using cement mortar which is consisted of water – sand – cement – building resin DOMORESIN SP.

2. APPLICATION OF SERITAL

– Existing Pool

1. In cases of old epoxy coating, it has to be relieved mechanically using sander.

2. In cases of old acrylic/hybrid, the surface is cleaned with sponge and water in order to remove the residual of salt, chlorine and dust.

3. The Components A and B are packed in pots with predetermined mixing ratio.

4. Component B is added to the component.

5. Mixing is done with low electrical mixer, in order to avoid the creation of bubbles during the mix.

6. Mixing time has to be at least 5 minutes, until the mixture is totally homogeneous. Ready for use mixture has to be applied within 45 minutes (at 20oC).

7. Mixed SERITAL is applied to the prepared substrate with brush, roller or spray gun (beck 19 – 23).

8. SERITAL has to be applied in 2 layers. The second layer is applied crossed, when the first layer is dry.

9. The final consumption of SERITAL is 500gr/m2.

– New Pool

1. Components A and B are packed in pots with the predetermined mixing ratio.

2. The component B is added to the component.

3. Mixing is done with low electrical mixer, in order to avoid the creation of bubbles during mixing.

4. Mixing time has to be at least 5 minutes, until the mixture is totally homogeneous. Ready for use mixture has to be applied within 45 minutes (at 20oC).

5. Mixed SERITAL is applied to the prepared substrate with brush, roller or spray gun (beck 19 – 23).

6. SERITAL has to be applied in 2 layers. The second layer is applied crossed, when the first layer is dry.

7. The final consumption of SERITAL is 500gr/m2.

NOTES:

1. In order to protect SERITAL from UV, we have to apply the transparent polyurethane aliphatic varnish SERITAL PT, as a final layer.

3. APPLICATION OF SERITAL PT

– SERITAL PT is applied with brush or roller. Using airless, the application is done with pressure 180 bar and nuzzle 0,015 – 0,017 inches.

4. CHARACTERISTICS OF THE SYSTEM

– Doesn’t need primer

– Can be applied even in liquid substrate and it’s not influenced by the moisture of the environment.

Read here the technical solution