Technical Support

+3023990 20321Synthetic Pool Membrane - FLAGPOOL

1. SUBSTRATE PREPARATION

– Existing Pool

Withdrawal of all accessories (lighting drains, etc.) that may be present in the pool area must be done.

1. Swimming pool with ceramic tiles:

Smooth all joints so that they will not be deleted after the application of the Liner.

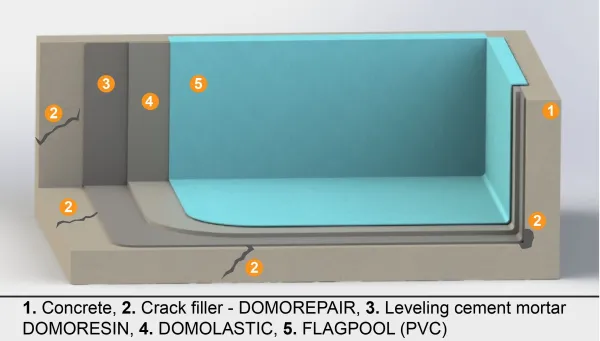

2. Swimming pool with concrete:

Equalize all unevenness of the substrate with mortar repair DOMOREPAIR R3.

– New Pool

1. Good cleaning of the application surface of oils, dust, loose materials etc.

2. In the parts of concrete where nests can be found, good cleaning of loose gravel is done.

3. Curtain and mourelatos are cut at a depth of at least 3cm.

4. Good cleaning of the above points and their restoration with mortar repair DOMOREPAIR R3.

5. In the case where the visible concrete presents unevenness, it is necessary to prior smooth the reinforced cement with the construction resin DOMORESIN SP.

2. MECHANICAL SUPPORT OF THE FLAGPOOL MEMBRANE

– Vertical Surfaces

1. Application of the special glue FLAGPOOLCOL to the coronation of the perimeter walls (welding zone width > 30cm).

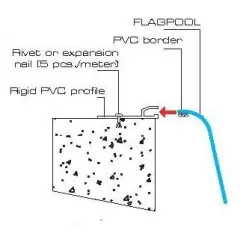

2. Mechanical bonding of FLAG special metallic profile (Figure 1).

To the films that will be applied to vertical surfaces, a special cord (PVC border), for anchoring them to the profile, is pasted with a hot air gun. The cord is applied to the back side of the FLAGPOOL films (synthetic PVC membrane reinforced with polyester mesh).

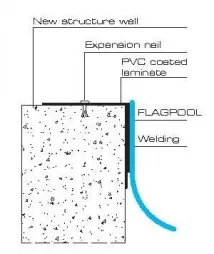

3. Mechanical bonding of a plasticized PVC blade to the perimeter and sealing of the film to it, as illustrated in Figure 2.

– Bottom

A mechanical bonding of the vertical portions of the membrane’s free ends is done on the bottom’s perimeter with the special FLAG connectors that reach the floor of the pool and ensure a perfect aesthetic result.

3. MEMBRANE APPLICATION

A thermal sealing of the rolls of the vertical surfaces is done with a hot air gun, with an overlapping of at least 4 cm, this is done before their mechanical fixing to the bottom.

The overlapping of the free horizontal sections of the bottom membrane with the already mechanically fixed vertical sections is at least of 4 cm.

A sealing of all seams with liquid PVC is further set to ensure their tightness and aesthetic result.

NOTES:

1. Filling the pool with water is done partially, this in order for the membrane to get its final position due to the hydrostatic pressure and to avoid failures in the implementation of special parts / accessories (lights, drainage etc.).

2. On the steps of the pool the non-slip membrane FLAGPOOL Antislip is applied.

Read here the technical solution