Technical Support

+3023990 20321No Inclination

This application concerns the thermal and waterproofing of an accessible roof, with a conventional synthetic PVC membrane. On a conventional roof, the waterproofing layer prevails the thermal insulation layer.

1. SURFACE PREPARATION

The surface should be sealed and before waterproofing, the following tasks are carried out:

– Good cleaning of the surface.

2. THERMAL & WATERPROOFING TASKS

– Vapor barrier

Creation of a vapor barrier with free spreading of polyethylene sheets PE.

– Screed Insulation

Placement of insulation boards.

– Layer Separation

Placement of geotextile non-woven polypropylene fibers with a minimum weight of 125 gr/m², DREFON S 125.

– Installation of synthetic PVC membrane with fiberglass reinforcement,FLAGON SV

1. The adhesion of synthetic membranes is performed with hot air apparatus (automatic or manual). In this way, the PVC melts on the surface, so that the adhesion will be achieved by a simple contact between them. The minimum width of the coating membranes to be glued is of 4 cm.

2. A free spreading of synthetic membrane follows and thermal gluing of the seams of its rolls with a hot air-gun.

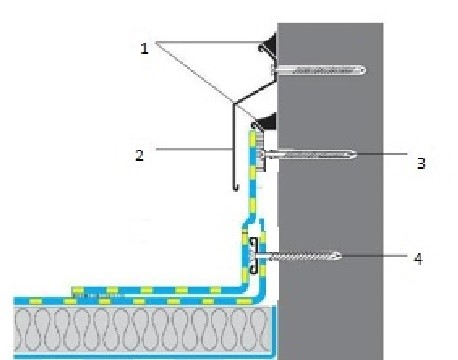

3. The roof’s waterproofing layer is fixed mechanically around a galvanized metal strip (Fig. 1/4), after being elevated up to 5cm on the parapet.

4. The parapet waterproofing is made with a synthetic membrane (angular aid lane) which rises on the parapet to a height of at least 20cm. The angular aid lane is mechanically fixed to the parapet either with a plasticized PVC strip (Fig.1/3) on which the membrane is pasted, or with a galvanized metal strip which is firmly fixed on the membrane, while on the roof it is welded to the membrane already mounted. A sealing of the waterproofing layer to the parapet with polyurethane mastic follows (Fig.1/1). Finally, for the integral protection of the system, an external dripper is installed and sealed onto the parapet (Fig.1/2)

Fig. 1: Mechanical mounting on parapet

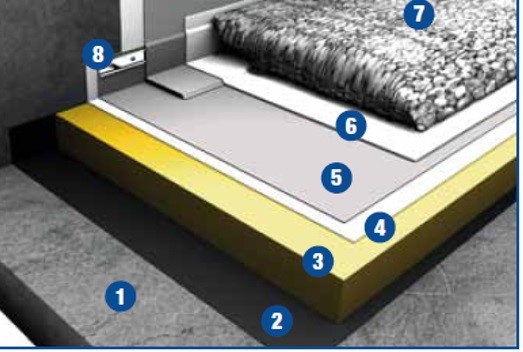

5. Finally, over the waterproofing layer, a protective layer of non-woven recycled polypropylene geotextile, 200g/m2 , Edilfon FR200, is placed and cross plied with gravel as a final layer (accessible roof, Fig. 2)

Fig.2: 1. Substrate. 2. Vapor barrier. 3. Thermal Insulation. 4.C/F. Separation. 5. Synthetic membrane PVC SV. 6.C/F. Protection. 7. Gravel layer. 8. Perimeter waterproofing fastening.

NOTES:

1. The above system can be also applied with a synthetic TPO membrane, with the difference that, in-between the insulating boards and the waterproofing, it is not necessary to insert a separation layer.

2. FLAG may conduct a grabbing study for the calculation of the mechanical support for the waterproofing layer on every roof.

3. Special gutter pieces, ventilation, inner & outer corners TPO/PVC of ETERNOIVICA will facilitate the implementation and optimize the final result.

Read here the technical solution