Technical Support

+3023990 20321Green Roof Construction

Α green roof – roof garden is gaining ever more ground compared to a conventional passable / non-passable roof, for environmental, practical and aesthetic reasons. Its construction requires the following tasks in order to ensure its functionality for waterproofing, drainage and filtration over time.

1. APPLICATION

– Roof:

Considering that the casting and insulation layer is already constructed, then freely place geotextile to separate and protect the forthcoming waterproofing layer from the substrate.

In the next step the implementation of the waterproofing layer follows, with free positioning of the synthetic membrane TPO, reinforced with fiberglass FLAGON EP / PV, on the substrate and weld the seams with a hot air gun. The synthetic membrane is placed mechanically to substrate perimeter only when is lifted up to 5cm from handrail, with galvanized metal blade.

NOTES:

1. TPOmembranereinforced withfiber glass (rather than polyesternest) will be coveredwithloadswithout requiringmechanical

– Guardrails:

Guardrails waterproofing is made with synthetic membrane (angular aid strip) which rises to the height of guardrails as the final surface of green roof. The angular aid strip is mechanically placed to the handrail, or by plasticized blade TPO on which the membrane is welded, or by galvanized metal strip which is firmly placed on the membrane. The roof is welded to the membrane which is already placed. Next follows the sealing of the waterproofing layer to guardrail with polyurethane mastic.

Next follows the free installation of geotextile to protect the membrane.

Then put the drainage layer (drainage panels of expanded polystyrene SOPRADRAIN SOPREMA) to ensure that water can circulate freely on the waterproofing layer, as the drainage panel has the necessary resistance to compression.

The filtration / filter layer (geotextile filtration by 100% continuous non-woven polypropylene fibers of SOPRAFILTER SOPREMA) follows, which only allows water to pass to the lower layers, in order to keep the drainage layer open and clean from dirt. The filtration layer is lifted on guardrails up to the level of waterproofing, and it is mechanically placed (higher than the last), providing protection to the synthetic membrane and to vertical surfaces.

In the final step, spread out the soil of the green roof. The composition and volume of which depend on the type of the selected planting of the green roof.

Similarly, the choice of the irrigation system depends on the type of planting and its required maintenance.

NOTES:

Around the roof is created a groove with gravel, in order to achieve traffic gutter (already done their waterproofing during construction of the waterproofing layer). The separation of the aggregate from the topsoil – soil is achieved by a metal profile (usually bent sheet whose dimensions are proportional to the respective solution).

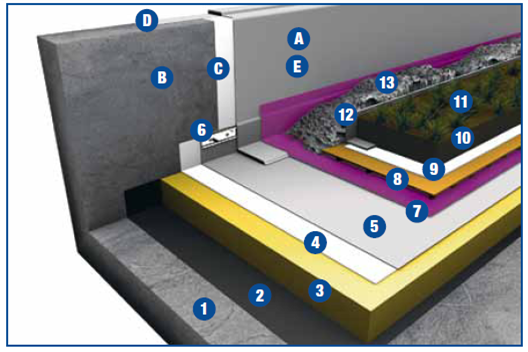

FIG. 1: Stratification of green roof

1. Substrate 2. Vapour barrier 3. Thermal insulation, 4 Geotextile, 5. Synthetic membrane TPO 6. Mechanical fastening blade, 7. Geotextile, 8. Drain layer 9. Geotextile filtration, 10. Topsoil 11. Planting, 12. Metal profiles 13. Perimeter groove gravel

NOTES:

1. Special gutter pieces, of internal and external angle TPO / PVC of the group ETERNOIVICA, facilitate implementation and optimize the final result.