Technical Support

+3023990 20321Synthetic Membrane

1. SUPPORTING ELEMENT OR SUBSTRATE

The substrate must:

– Be smooth, sound, clean and free from debris and irregularities that may cause damage to the layers above.

– Be stable over time.

– Be chemically compatible with the roofing system components.

– Be suitable for mechanical fixing.

2. THERMAL & WATERPROOFING INSULATION PROCESS

– Vapour Barrier

It depends upon the hygrometry of the underlying structures. A vapour retarder may consist of polyethylene film.

– Insulation Element

Application of the insulation boards of extruded polystyrene.

The insulation boards should be fully bonded in order to avoid unabsorbed water and allow the overlaps to be adequately hot air welded.

– Separating Layer

Nonwoven polypropylene fibres geotextile whose weight ranges from minimum 200 g/m2 depending upon the condition of the support.

– Sealing Element

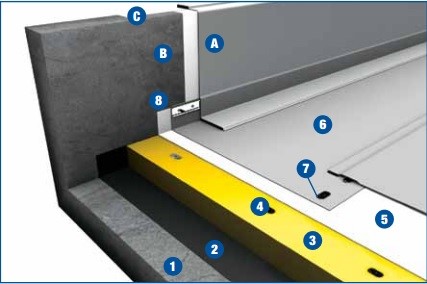

FLAGON SR, synthetic membrane in PVC-P reinforced with a polyester mesh, resistant to tearing under wind stress, resistant to ultraviolet rays, to puncturing, to weathering, and to root growth. It has signal layer and it is heat welded on the sheet overlaps. Mechanical fixing is made by expansion fixing plugs and distribution plates for concrete substrate. The perimeter fixing at the base of the upstand must be performed with FLAG pre-drilled bar in galvanised sheet iron. Insert Flag anti-puncturing joint at the junction between two adjacent bars and hot weld the tear prevention curb FLAGOFIL PVC.

Horizontal surface:

1. Supporting element

2. Vapour Barrier

3. Insulation element

4. Fixing elements

5. Separating layer

6. FLAGON SR Membrane fixing elements

7. Perimeter pre-drilled bar

Vertical surface:

1. FLAGON SR

2. h50 cm mechanical fixing

3. Separating layer in non-woven felt (non-adhered roof system)

Read here the technical solution