Technical Support

+3023990 20321Steel Deck construction

1. BASIC PRINCIPLES

The waterproofing of a steel roof presents a number of particularities compared to ordinary concrete roofs.

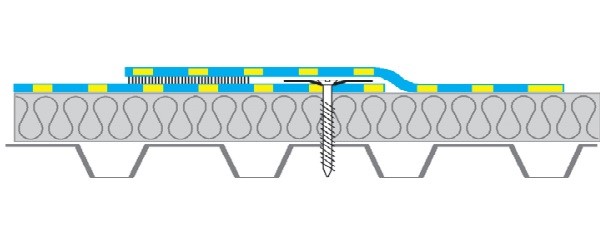

The cross section of the trapezoidal metallic sheet defines the manner in which the mechanical fixation of the waterproofing layer will be set (Seizure study) (Fig.1).

Fig.1 Mechanical mounting on trapezoidal sheet

The most appropriate solution in this case is the application of synthetic membrane thermoplastic polyolefin TPO.

2. APPLICATION:

– Initially, a stratification of the polyethylene PE sheet is created as a vapor barrier on top of the trapezoidal metal sheet, in order to protect the insulation layer from possible condensation. On top of the vapor barrier a stratification of insulation boards is created, ensuring a stable substrate and on which the waterproofing layer will be mechanically fixed. The insulation boards are bonded mechanically on the trapezoidal metal sheets to prevent their seizure, due to pressure exerted on the roof.

– A stratification of the synthetic membranes TPO EP/PR is further created and reinforced with a polyester mesh, which imparts mechanical strength to the film and allows mechanical attachment.

– The mechanical fixation of TPO membrane to the substrate follows (trapezoidal metal sheet + insulating plates, Fig.1) according to the Seizure study and thermal seams. The coating of the rolls varies according to the hot air welding machine to be used, this from 4cm to 12cm.

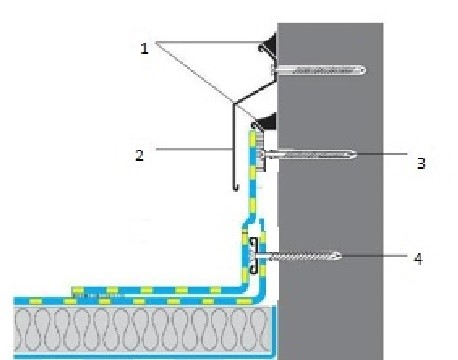

– The waterproofing layer of the roof is fixed mechanically around a galvanized metal strip (Fig. 2/4), further being elevated up to 5cm on the parapet.

Fig.2

– The parapets waterproofing is made with a synthetic membrane (gusset strip aid) which rises to a height of at least 20cm on the parapets. The gusset strip is mechanically fixed to the parapet, either with a laminated blade TPO (Fig.2/3) on which the membrane is pasted, either with a galvanized metal strip firmly fixed on the membrane, while on the roof it is welded to the already mounted membrane. A sealing of the waterproofing layer follows on the parapet with polyurethane mastic (Fig.2 / 1).

– Finally, for the integrated protection of the system to the parapet, an external emitter is installed and sealed (Fig.2/2).

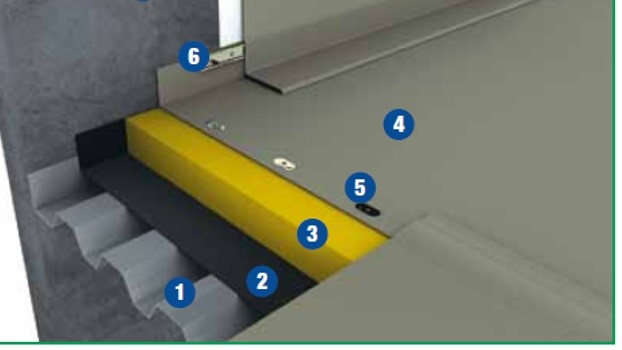

The above system is illustrated in details on the following scheme.

Fig.3: 1. Trapezoidal metallic sheet. 2. Vapor barrier. 3. Thermal insulation. 4. Synthetic TPO membrane EP/PR1,5. 5. Mechanical fastening. 6. Perimeter support.

NOTES:

1. The above system can also be applied to synthetic PVC membrane, with the difference that between the insulating plates and the waterproofing a non-woven geotextile 200g/m2 must be set, as a separation layer, to prevent the polymerization of plasticizers of PVC film with polystyrene.

2. FLAG may conduct a Seizure study for the calculation of the mechanical supports of the waterproofing layer on every roof.

3. Special gutter pieces, ventilation, inner and outer corner TPO/PVC from ETERNOIVICA facilitate the implementation and optimization of the final result.

Read here the technical solution