Technical Support

+3023990 20321Warertight Basin Construction

Warertight Basin Construction

1. BASIC PRINCIPLES

– The penetration ofwaterand humidityin building materialscauses hugedamage, i.e.:

1. Corrosion and weathering.

2. Chemicalcorrosion andoxidation of the concrete steel reinforcement.

3. Createrashesand spots.

4. Growth offlora, lichensand fungous.

– Most of the above are derived from the direct effect of moisture, along with the physical and chemicalproperties of waterand the correspondingbuilding materials. Anotheraspect is thesignificant increase of watervolume (10%) from the effect of frost, when converted fromliquidtosolid form. The disastrous effect of frost is due to each material’s porosity and the quantity of water that has already been absorbed.

– For the effective protection of the building’s foundations, when the horizontal water table is at the same or higher level than the foundations of the buildings, or there is vicinity with the sea, it is recommended the creation of a watertight basin using the FLAG synthetic membranes, produced by SOPREMA.

– The watertight basin creates a waterproofed cover of the building’s foundation, until the ground’s level.

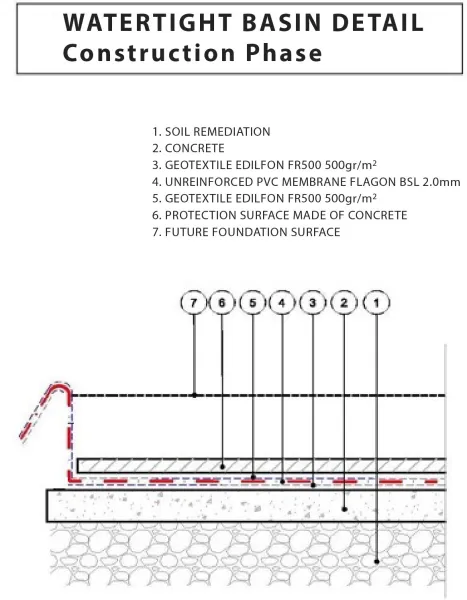

2. APPLICATION (Fig.1)

– Before the application of the watertight basin, it is essential to create a drainagelayerbeneath thefoundation(non-woven geotextilefrom virginpolypropylenefibers, weight: 200g/m2, specific type DREFON S200, 40cm gravel layer).

– Then, a separating layer is applied with a polyethylene sheet and concrete cleaning layer, reinforced with steel mesh.

– Above the cleaning concrete, a coating of protective layer is applied with a non-woven geotextile from recycled polypropylene fibers, weight 500gr/m2 EDILFON FR500.

– Further, a free placement of the synthetic membrane PVC FLAGON BSL is applied, 2,0mmthickness and the welding of the seams takew place through a hot airwelding.

– Finally, a coating of protective layer of non-woven geotextile from recycled polypropylene fibers is applied; weight 500gr/m2 EDILFON FR500.

Fig. 1

NOTES:

1. The synthetic membrane and the bottom protective layers are protruded from the vertical elements at 0.5-0 m.in order to ensure their good weldingwith the relevant partsof the walls(Fig. 1).

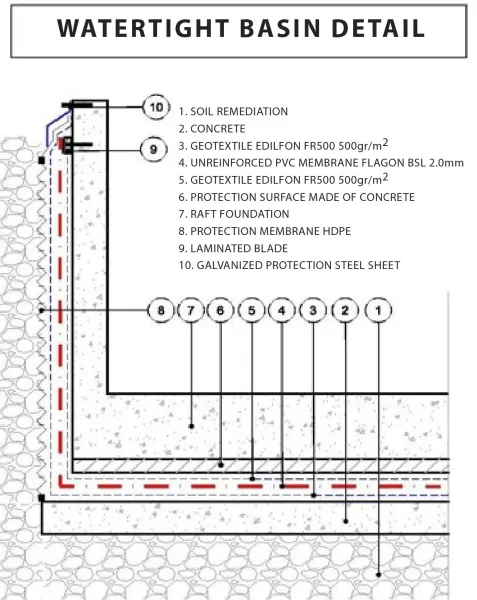

On vertical surfaces (Fig. 2), a mechanical bonding is applied at the ground level and a free placement towards the bottom of a geotextile protection and synthetic membrane. The mechanical bonding of the membrane is applied with plasticized PVC blade, 5,0cm width. The welding of the seams follows with a hot-air welding device.

Fig. 2

The sealing of the watertight basin is applied at its end on the ground surface (bonding point in plasticized PVC blade) with polyurethane mastic.

Finally, a protective and drainage layer is placed above the geotextile protection, ensuring the additional protection of the waterproofing, either during the phase of earth backfilling (it has to be done separately with the appropriate materials), or the drainage of water towards the bottom’s layer of gravel.

Read here the technical solution